Decoding the Cost: A Comprehensive Guide to Rice Mill Prices

The global demand for rice, a staple food for over half the world’s population, continues to grow. This consistent demand makes the rice milling industry a highly lucrative venture. For entrepreneurs and established businesses looking to enter or expand in this sector, a crucial initial step is understanding the “Rice Mill Price.” This isn’t a single, fixed figure; rather, it’s a dynamic sum influenced by a multitude of factors.

At Ricetec Machinery, we understand that investing in rice milling equipment is a significant decision. As a leading manufacturer, supplier, and exporter of innovative and technologically advanced modern grain processing machinery since 2004, we are committed to providing not only world-class machinery but also comprehensive insights to help our customers make informed choices. This blog will delve deep into the various aspects that determine rice mill prices, empowering you with the knowledge to select the ideal solution for your specific needs.

Understanding the Rice Milling Process: A Prerequisite to Pricing

Before we dissect the pricing factors, it’s essential to grasp the fundamental steps involved in modern rice milling. Each stage often requires specialized machinery, contributing to the overall cost:

1. Pre-cleaning

Raw paddy, directly from the fields, contains impurities like dust, straw, stones, and foreign particles. Pre-cleaners remove these to ensure efficient hulling and better milling recovery.

2. Dehusking (Shelling)

This crucial step removes the outer husk from the paddy to produce brown rice. Efficient shellers, like Ricetec’s Pneumatic Rubber Sheller, minimize grain breakage and maximize yield.

3. Paddy Separation

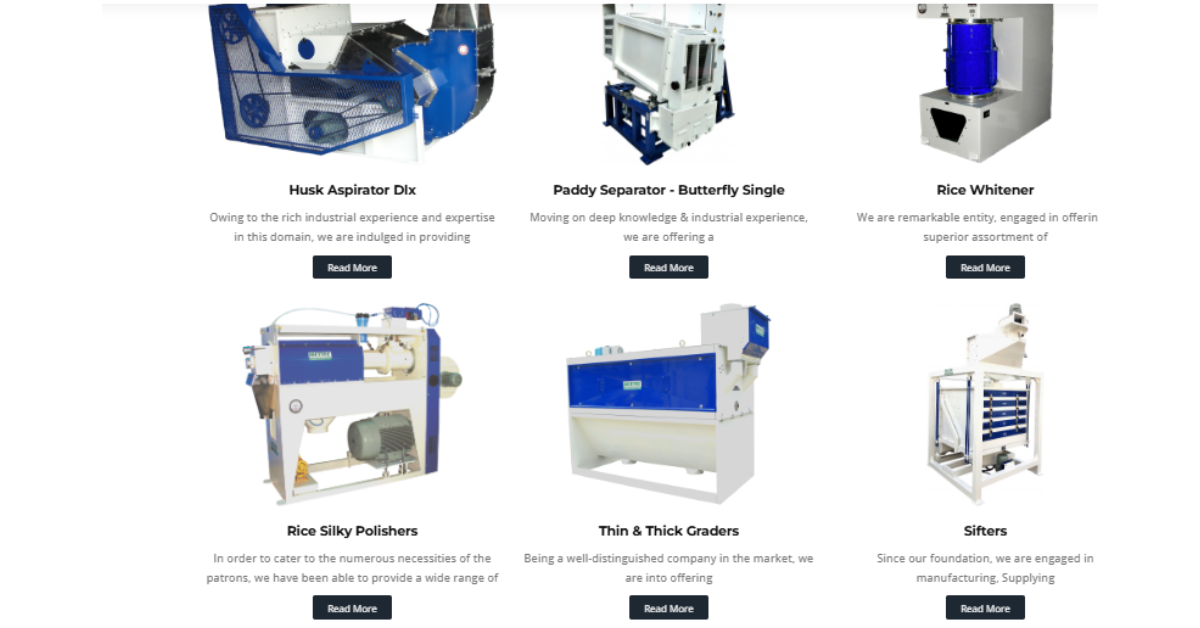

After dehusking, some unhusked paddy may remain. Paddy separators efficiently separate these from the brown rice, ensuring only brown rice proceeds to the next stage.

4. Whitening or Polishing

This stage removes the bran layer and germ from the brown rice to produce polished white rice. This is typically done in multiple passes using rice whiteners and silky polishers to achieve the desired luster and minimize breakage.

5. Grading and Sorting

Milled rice is then separated into different grades based on size and quality (e.g., head rice, large broken, small broken). Advanced systems like color sorters are used to remove discolored or damaged grains, significantly enhancing the final product’s quality.

6. Mist Polishing (Optional)

For an even brighter and more lustrous finish, some mills incorporate mist polishers.

7. Weighing and Packaging

The final product is accurately weighed and packaged for distribution.

Each of these steps, or combinations of them, can be handled by individual machines or integrated systems, directly impacting the overall rice mill price.

Key Factors Influencing Rice Mill Price

The cost of a rice mill can vary dramatically, ranging from a few lakhs for a small-scale unit to several crores for a fully automated, large-capacity plant. Here are the primary factors that contribute to this variation:

1. Scale of Operation and Capacity

This is arguably the most significant determinant of rice mill price.

- Mini/Small-Scale Rice Mills: Designed for smaller farmers, rural communities, or those with limited capital, these mills typically process 1-5 tons per day. They are often less automated, require more manual intervention, and are the most affordable option.

- Medium-Scale Rice Mills: Ideal for growing businesses, these mills can process 10-50 tons per day. They offer a balance between automation and cost, providing higher efficiency than mini mills without the substantial investment of large-scale plants.

- Large-Scale/Commercial Rice Mills: These are fully automated, high-capacity plants capable of processing 50+ tons per day. They are designed for continuous operation, high yield, and superior rice quality, demanding a significant investment.

Naturally, as the capacity increases, so does the size, complexity, and cost of the machinery required.

2. Level of Automation

The degree of automation profoundly impacts the price.

- Manual/Semi-Automatic Mills: These require more human labor for various stages of the milling process. They are generally less expensive upfront but may incur higher operational costs due to labor.

- Fully Automatic Mills: These systems minimize human intervention, with integrated sensors, programmable logic controllers (PLCs), and automated controls managing the entire process from paddy intake to final packaging. While their initial cost is higher, they offer superior efficiency, consistency, reduced labor costs, and higher yields in the long run.

3. Technology and Features

Modern rice milling machinery incorporates advanced technologies that enhance efficiency, product quality, and reduce losses.

- Advanced Cleaning Systems: Vibratory cleaners, destoners, and magnetic separators contribute to cleaner paddy and better milling.

- Efficient Dehuskers: Rubber roll shellers are preferred over traditional hullers for higher shelling efficiency and less breakage.

- Multi-Stage Polishers: Using multiple polishing machines in series ensures a higher degree of whiteness and luster with minimal grain damage.

- Color Sorters: These highly sophisticated machines use optical sensors to identify and remove discolored, broken, or defective grains, significantly improving the market value of the final product. The inclusion of a color sorter can substantially increase the overall price.

- Grading and Sifting Systems: Precision graders ensure consistent rice kernel sizes.

- Energy Efficiency: Modern machines are designed to be energy-efficient, which can lead to significant long-term savings on electricity bills, though the initial cost might be higher.

4. Material and Build Quality

The durability and longevity of a rice mill are directly tied to the materials used in its construction and the quality of manufacturing.

- Robust Construction: Machines built with high-grade steel and durable components will naturally cost more but offer extended operational life and require less frequent maintenance.

- Wear-Resistant Parts: Components exposed to constant friction, like rubber rollers and screens, need to be made from high-quality, wear-resistant materials. Superior quality parts translate to a higher price but lower replacement costs over time. Ricetec Machinery prides itself on using superior-grade raw materials and cutting-edge technology, ensuring our machines not only meet but exceed industry standards.

5. Brand Reputation and After-Sales Support

Established manufacturers with a strong reputation for quality, reliability, and excellent after-sales service often command higher prices. This is because they offer:

- Proven Performance: A track record of successful installations and satisfied customers.

- Warranty and Guarantees: Assurance of product quality and support in case of defects.

- Technical Support and Spare Parts Availability: Critical for minimizing downtime and ensuring smooth operations. Ricetec Machinery offers 24×7 service support and state-wise service hubs across India for prompt service, a testament to our commitment to customer satisfaction.

6. Installation and Infrastructure Costs

The total project cost extends beyond just the machinery.

- Land and Building: The cost of acquiring land and constructing a suitable building to house the mill varies significantly based on location.

- Installation Charges: Setting up and commissioning the machinery requires skilled labor, which adds to the overall expense.

- Utilities: Ensuring a stable supply of electricity and water, and the associated infrastructure, can also be a considerable cost.

7. Transportation and Import Duties (if applicable)

For international buyers, shipping costs, customs duties, and local taxes will add to the overall rice mill price. Even within a country, transportation costs can vary depending on the distance from the manufacturer.

Estimated Price Ranges (Illustrative)

While providing exact figures is challenging due to the customizability and varying specifications of rice mills, here’s a broad illustrative range for the machinery component in India:

- Mini Rice Mills (1-2 TPH): ₹2 Lakhs to ₹10 Lakhs

- Small-Scale Automatic Rice Mills (2-5 TPH): ₹10 Lakhs to ₹35 Lakhs

- Medium-Scale Automatic Rice Mills (5-10 TPH): ₹35 Lakhs to ₹80 Lakhs

- Large-Scale/Commercial Fully Automatic Rice Mills (10+ TPH): ₹80 Lakhs to ₹5 Crore or more, depending heavily on automation, advanced features, and integrated solutions.

It’s crucial to remember that these are approximate figures and can fluctuate based on market conditions, technological advancements, and specific customizations. For precise pricing, it is always recommended to contact manufacturers directly with your detailed requirements.

Investing Wisely with Ricetec Machinery

Choosing the right rice mill is a strategic investment that can significantly impact your business’s profitability and long-term success. At Ricetec Machinery, we believe in maximizing the profitability of millers while minimizing food grain loss. Our focus on continuous innovation through in-house R&D ensures we offer optimal performance, high energy efficiency, and low cost of ownership.

When considering the rice mill price, look beyond the initial outlay. Factor in the long-term benefits such as:

- Increased Yield: Superior machinery leads to higher recovery of quality rice from paddy.

- Reduced Labor Costs: Automation streamlines operations and minimizes the need for extensive manual labor.

- Improved Rice Quality: Advanced polishing and sorting result in a premium product that fetches better market prices.

- Lower Maintenance: Durable machines built with quality materials require less frequent repairs and downtime.

- Energy Savings: Efficient designs translate to lower electricity consumption.

Ricetec Machinery is an ISO 9001:2015 and CE certified company, manufacturing to European markets. With over 3000 satisfied customers in India and neighboring countries, we have earned a reputation as a solid brand built on quality, convenience, reliability, and economy.

We invite you to explore our comprehensive range of machinery, integrated processing systems, and total engineering solutions for processing paddy, wheat, dal, maize, and all varieties of grain. Our dedicated team of qualified and highly experienced engineers is ready to help you navigate the complexities of rice mill pricing and find the perfect solution to meet your specific production goals and budget.

Frequently Asked Questions (FAQ)

Q1: What is the most important factor influencing rice mill price?

The scale of operation and desired processing capacity (e.g., tons per hour) is generally the most significant factor affecting the rice mill price. Larger capacities and higher throughput necessitate bigger, more complex, and thus more expensive machinery.

Q2: Is it always better to buy a fully automatic rice mill, even if it’s more expensive?

While fully automatic rice mills have a higher initial cost, they often provide significant long-term benefits such as reduced labor costs, higher efficiency, consistent product quality, and lower operational losses, which can lead to a quicker return on investment for larger-scale operations. For smaller operations, a semi-automatic or manual mill might be more cost-effective.

Q3: How do I get an accurate price quote for a rice mill from Ricetec Machinery?

To get an accurate price quote, it’s best to contact us directly. We will need details about your desired processing capacity, the level of automation you require, specific features like color sorters or advanced polishing units, and your location for transportation cost estimation. Our team will then provide a customized solution and detailed pricing.

Q4: Does the type of rice being milled affect the machinery cost?

Generally, the core machinery remains similar, but specific requirements for different rice varieties (e.g., Basmati, raw paddy, parboiled) might necessitate fine-tuning of machine settings or the inclusion of specific accessory equipment to achieve optimal results, which could subtly influence the overall price.

Q5: What kind of after-sales support can I expect from Ricetec Machinery?

Ricetec Machinery offers comprehensive after-sales support, including on-site installation, technical assistance, easy maintenance guidance, and the availability of genuine spare parts. We have dedicated service hubs across India and offer 24×7 service support to ensure minimal downtime for our customers.